How To Build A Reverse Osmosis System For Maple Sap

How to build a reverse osmosis system for maple sap. Thus concentrating everything else including sugar. Sap goes into rain barrel need valve out from rain barrel. The membrane allows water molecules through but forces the sugar molecules to pass over it essentially reducing the amount of water in the sap with each pass of the liquid through the system.

When the maple sap comes out of the tree it tastes pretty much like water. Reverse Osmosis is a process typically used for water purification. Reverse osmosis uses pressure to force a liquid in this case maple sap over a membrane.

This Instructable demonstrates how to make a DIY Maple Sap Reverse Osmosis Unit suitable for processing maple sap. A technique for purifying water in which pressure is applied to force liquid through a semipermeable membrane in the opposite direction to that in normal osmosis. What is Reverse Osmosis.

Finished maple syrup is 67 sugar. Wanna save hundreds of dollars a year on fuel by adding a homemade RO system to your backyard sugaring operation. In my housing the membrane installs like this.

These RO units can be used to remove water from sap to speed up the concentration and syrup boiling process. This Instructable demonstrates how to make a DIY Maple Sap Reverse Osmosis Unit suitable for processing maple sap. It takes 40 or more gallons of maple sap to make one gallon of maple syrup.

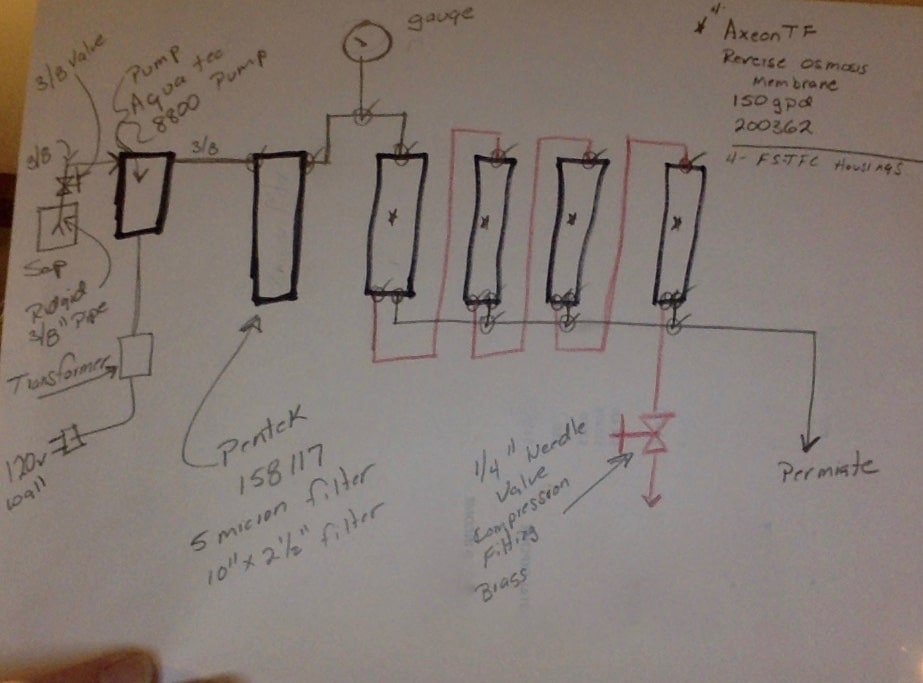

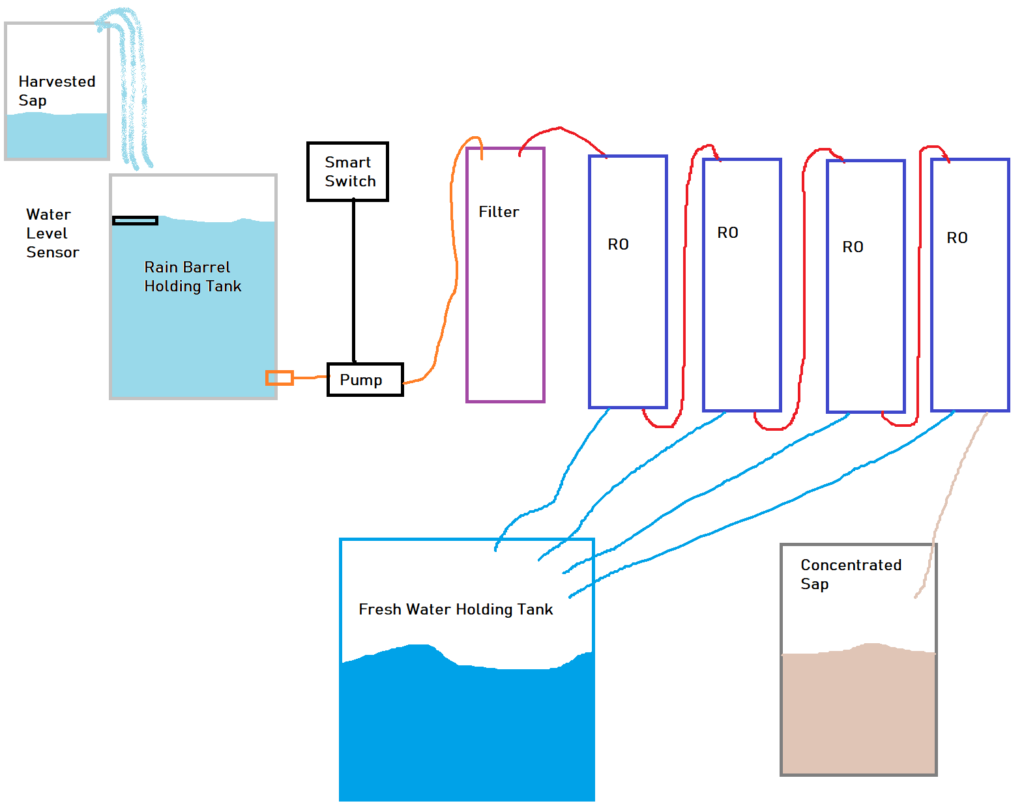

Separation by reverse osmosis Up to two-thirds of the water in maple sap can be separated by using reverse osmosis before the boiling process which will reduce the boiling time and relative energy costs. Capacity is suitable for small to moderate syrup operations with 250 - 600 taps. DIY Reverse Osmosis Filter for Maple Sap Notes from the reverse osmosis system build we are planning.

Then I was introduced to Reverse Osmosis. Here is an overview of my homemade Reverse Osmosis system for concentrating maple sap.

Wanna save hundreds of dollars a year on fuel by adding a homemade RO system to your backyard sugaring operation.

Our maple syrup operation manager aka hubby built a reverse osmosis RO filter system that we run our sap through before boiling. This Instructable demonstrates how to make a DIY Maple Sap Reverse Osmosis Unit suitable for processing maple sap. DIY Reverse Osmosis Filter for Maple Sap Notes from the reverse osmosis system build we are planning. Separation by reverse osmosis Up to two-thirds of the water in maple sap can be separated by using reverse osmosis before the boiling process which will reduce the boiling time and relative energy costs. Ensure you put your Reverse Osmosis Membrane in correctly. These RO units can be used to remove water from sap to speed up the concentration and syrup boiling process. The system will extractremove water from sap. However these reverse osmosis systems are typically too expensive for home producers to afford. A semi-permeable membrane is used to separate water from sugar minerals and other impurities.

That means our boiling time is cut by 75. That means our boiling time is cut by 75. Sensor in sap holding tank and smart outlet for pump turn off pump when tank is near empty. Removing two thirds of the water before boiling. Operating the RO system at 120 to 200 psi applied membrane pressure will efficiently reduce the sap to a consistency suitable for boiling. Our maple syrup operation manager aka hubby built a reverse osmosis RO filter system that we run our sap through before boiling. In the maple industry we use reverse osmosis systems but instead of keeping the purified water we keep the concentrated sugar minerals and other impurities as concentrated maple sap to finish boiling into maple syrup.

Post a Comment for "How To Build A Reverse Osmosis System For Maple Sap"